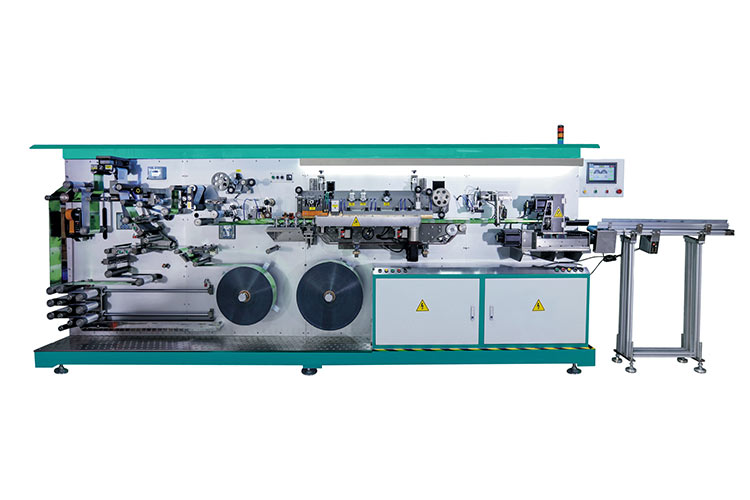

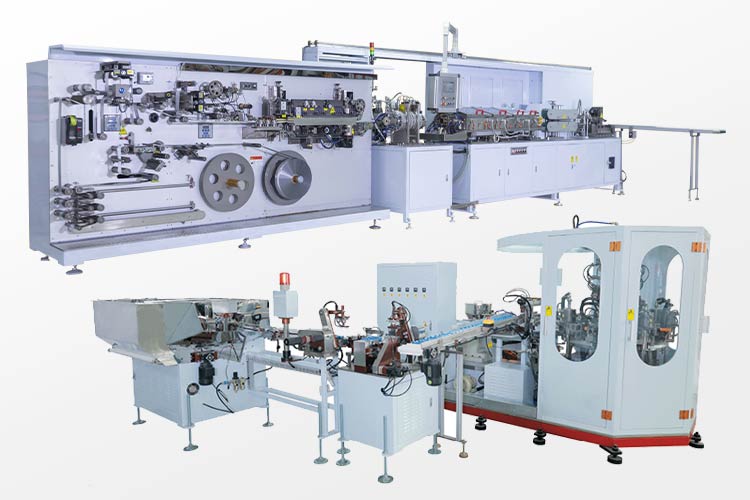

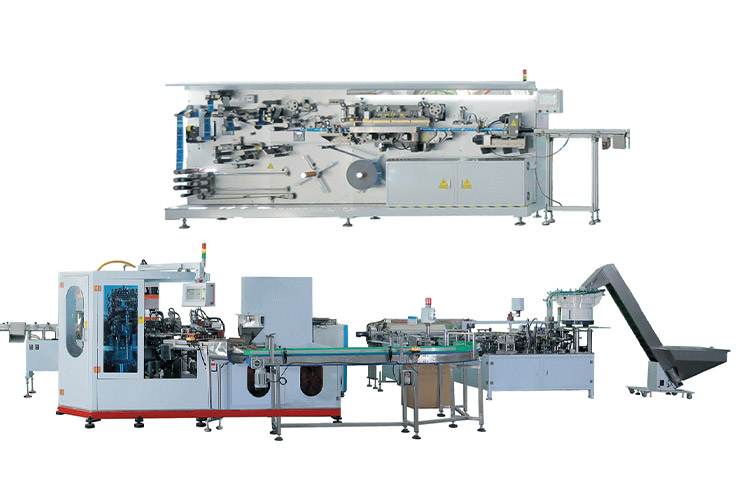

Lami Tube Making Machine

Laminated Tube Making Machine

High-Speed Production for Lami Tube

Ideal for Various Lami Tube Applications

What is Lami Tube Making Machine?

Lami tube making machine, as an efficient and automated lami tube production equipment, is widely used in the packaging production of multiple industries such as cosmetics, personal care, pharmaceuticals or food industries. Lami tube making machine can provide safety protection and a good experience for products. With the advancement of technology and the increasing demand for environmental protection, the application scope of laminated tube making machine will continue to expand, providing innovative packaging solutions for more industries.

Lami Tube Making Machine Overview

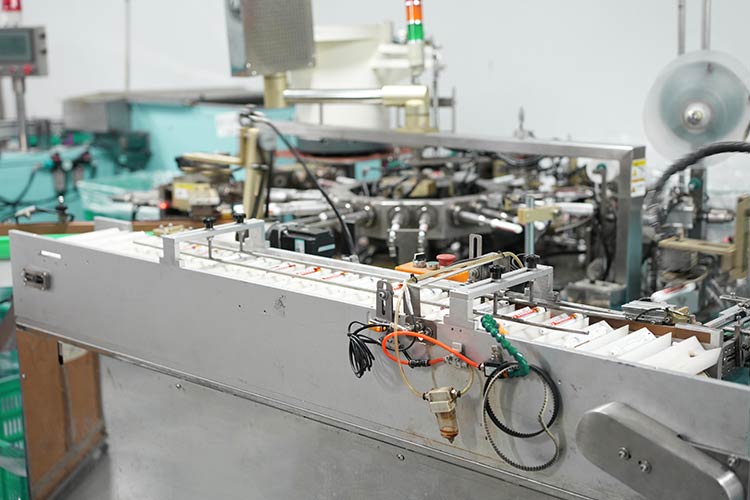

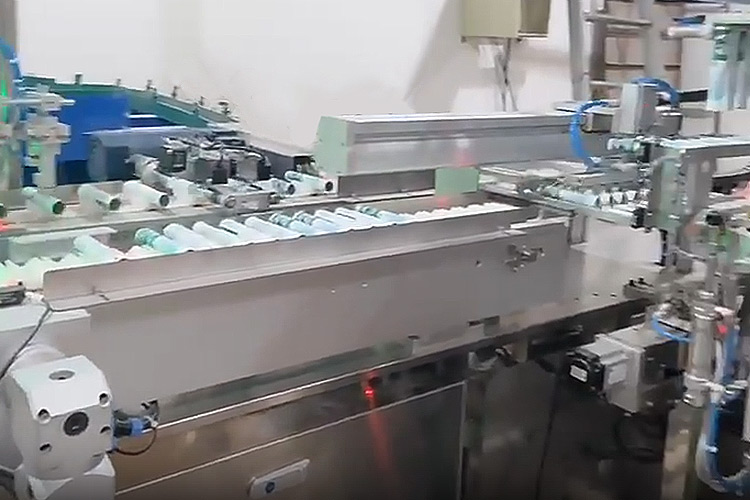

Lami Tube Making Machine Installation Cases

Features of Lami Tube Making Machine

- Fully Automation and High-Efficiency

- Extensive Raw Materials

- Multi-Layer Structure Design

- High-Precision Control System

- Various Specification Production

- Energy-Efficiency Optimization System

Why Choose Our Lami Tube Making Machine?

Ensure high degree of consistency in indicators

Achieve standardized large scale production

Reduce manual intervention with intelligence

Increase production capacity and output

Optimize thermal management system

Reduce energy waste and heat loss

Provide multiple data control function

Simply operate and less manual intervention

Meet the diverse production demands

Reduce the overall operating cost

Supply tubes with multiple specifications

Adapt packaging requirements of various tubes

| Features | Lami Tube Making Machine | Traditional Single-Layer Tube Making Machine |

|---|---|---|

| Product |  |  |

| Working Process | Form tube blank by heat lamination | Form tube blank by extrusion |

| Raw Material | Multi-layer composite film (ABL, PBL) | Melted plastic pellets |

| Product Performance | Excellent barrier properties and exquisite appearance | Ordinary barrier properties and product appearance |

| Produce Efficiency | Fast and suitable for large scale production | Low production speed and difficult for large scale production |

| Application | High requirements for packaging quality | Ordinary requirements for packaging quality |

Application of Lami Tube Making Machine

What Type of Tubes Can Be Made with Lami Tube Making Machine?

How to Use Lami Tube Making Machine for Tube Manufacturing?

-

Material preparation

Fix the multi-layer composite film (such as ABL film, PBL film) on the equipment frame. The quality and specifications of film rolls are key to ensuring the stability of subsequent production.

-

Film unfolding and pretreatment

Spread the film rolls smoothly and remove dust to enhance surface cleanliness and adhesion. Include heating pretreatment to bring the film to an appropriate softening temperature.

-

Lamination forming

This is a core production process. Under controlled temperature and pressure, materials are tightly bonded to form a tube blank. Precisely control temperature distribution and pressure to ensure each layer is free of bubbles.

-

Cooling and setting

The formed tube blank is rapidly cooled and shaped to ensure uniform wall thickness and structural stability. Rapid cooling helps prevent deformation or adhesion and ensures accuracy for subsequent cutting and tail sealing.

-

Sealing and cutting

Via the automatic conveying system, the tube blank enters the sealing and cutting process to ensure air-tightness and leak-proof performance. The tube is then automatically cut into single finished products. This step requires high precision and stability to avoid defects.

-

Quality inspection and packaging

An automated system inspects finished tubes (size measurement, sealing performance tests, etc.). Qualified tubes are conveyed to packaging for classification, boxing, and sealing.