Plastic barrier laminate, known as PBL, is a laminated packaging material designed for high product protection and sustainability. Companies choose eco-friendly materials like PBL because less than 10% of plastic waste is recycled globally, making recyclable options crucial for reducing environmental impact.

- The shift toward eco-friendly packaging comes from sustainability concerns and regulatory changes.

- Lightweight laminated structures help lower emissions and improve logistics. A lami tube making machine produces PBL tubes efficiently, supporting the move to recyclable, laminated tube packaging. Compared to alternatives such as ABL, PBL offers better recyclability with strong environmental benefits.

Key Takeaways

- Plastic barrier laminate (PBL) is a sustainable packaging option that helps reduce plastic waste and supports recycling efforts.

- PBL tubes provide strong protection against moisture, oxygen, and light, which helps keep products fresh and extends their shelf life.

- Using PBL can lower greenhouse gas emissions and energy usage compared to traditional packaging materials like glass.

- Many industries, including cosmetics, food, and pharmaceuticals, benefit from PBL due to its versatility and eco-friendly features.

- Innovations in PBL technology, such as mono-material designs, enhance recyclability and support a circular economy.

Plastic Barrier Laminate Overview

What Is PBL?

Plastic barrier laminate, often called PBL, is a multi-layered packaging material designed to provide strong barrier protection and maintain product integrity. Manufacturers use laminated structures to combine several materials, each offering unique benefits. The outer layer usually consists of polyethylene terephthalate (PET), which gives high strength and heat resistance. The middle layer often features aluminum foil, delivering the highest barrier protection against gases, moisture, and light. The inner layer typically uses polyethylene (PE) to seal the product and prevent leaks.

Laminated plastic is a composite material formed by bonding layers of different substances. This process includes components such as aluminum and low-density polyethylene (LDPE). High-frequency pressing and heating bond these layers together, creating a durable and protective packaging solution.

| Component | Description |

|---|---|

| Outer Layer | Made of polyethylene terephthalate (PET), known for high strength, heat resistance, and excellent barrier against oxygen. |

| Middle Layer | Composed of Aluminum foil, providing the highest barrier performance against gases, moisture, and light. |

| Inner Layer | Typically a sealant layer made of Polyethylene (PE). |

Structure and Materials

The structure of plastic barrier laminate relies on advanced materials that enhance barrier protection and extend shelf life. Manufacturers select materials based on their ability to block moisture, oxygen, and contaminants. Common materials include:

| Material | Contribution to Barrier Properties |

|---|---|

| Polyvinylidene chloride (PVDC) | Provides excellent barrier against oxygen and moisture |

| Polyamide (PA) | Enhances mechanical strength and gas barrier |

| Ethylene Vinyl Alcohol (EVOH) | Offers superior oxygen barrier properties |

| Polypropylene (PP) | Provides rigidity and moisture resistance |

Laminated tube packaging often uses EVOH as a barrier layer, which helps preserve product integrity and extend shelf life. Innovations in laminated tube technology have introduced biodegradable and water-soluble polymers, making recycling easier. Some laminated tubes now use cellulose-based films with high renewable content or starch-polymer blends that offer up to 95% biodegradability. Bio-PE laminates can reduce carbon footprint by 60%, supporting environmental goals.

Manufacturers also develop single-material high-barrier solutions for laminated tubes, which eliminate the need for complex multi-material layers. These tubes can contain up to 55% recycled content, promoting a circular economy. Metal-free laminates provide high barrier protection against moisture, oxygen, and light while remaining compatible with existing recycling streams.

Laminated Tube Making Machine

The laminated tube making machine plays a crucial role in producing laminated tubes with consistent quality and barrier protection. The process involves several steps:

- The machine starts with rolls of laminate feed stock, known as web stock, which contains various polymers and a barrier layer.

- Printing methods such as offset, letterpress, flexographic, or digital printing apply graphics and information to the web stock.

- The printed web stock unrolls and passes through forming rolls, shaping it into a cylinder.

- High-frequency heat fuses the sides of the laminated material, creating a long cylindrical sleeve.

- The sleeve is cut into smaller, uniform lengths at a cutting station.

- The tube sleeve moves to the heading operation, where the machine forms the shoulders using in-line injection or compression molding, or by attaching preformed shoulders.

- In in-line molding, molten plastic forms the tube head, which fuses to the tube body using heat.

Laminated tube production with the lami tube making machine offers several environmental benefits. Tubes are recyclable in various waste streams, and recycling reduces environmental impact. Energy recovery is possible through incineration, further supporting sustainability.

| Benefit | Description |

|---|---|

| Barrier Protection | Prevents moisture, light, air, and contaminants from affecting the product, maintaining quality. |

| Recyclable and Sustainable | Many tubes are recyclable, contributing to sustainability efforts and reducing environmental impact. |

| Product Protection | Protects against UV radiation, temperature changes, and contamination, preserving product integrity. |

Manufacturers focus on developing ecological laminated tube options. These tubes support a circular economy and help reduce waste. Innovations such as surface treatments and coating formulations enhance recyclability. The use of recyclable plastic alternatives reduces hard plastics in circulation, making laminated tube packaging a greener choice.

PBL vs. ABL

Key Differences

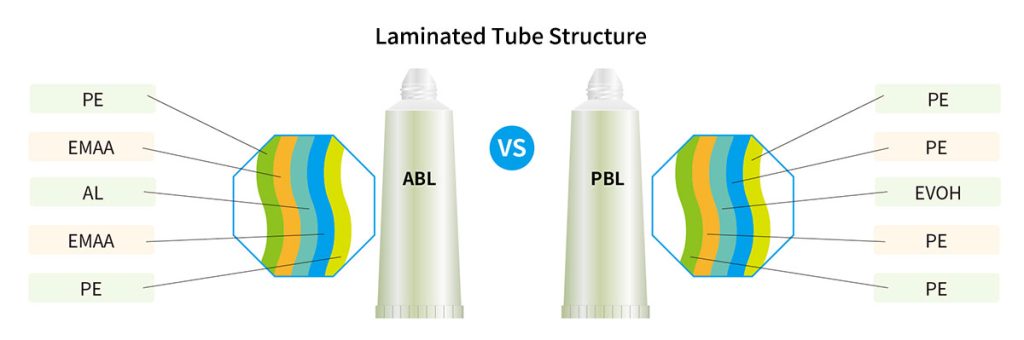

Plastic barrier laminate and aluminum barrier laminate both serve as popular choices for laminated tube packaging, especially in cosmetic packaging. However, they differ in several important ways:

- Aluminum barrier laminate tubes provide excellent barrier protection against oxygen, light, and moisture. This high-barrier protection is essential for preserving sensitive products and maintaining product integrity.

- Plastic barrier laminate tubes offer strong barrier protection, but they do not match the superior performance of aluminum in blocking moisture, oxygen, and light. As a result, aluminum laminated tubes remain the preferred option for products that require long shelf life and maximum product protection.

- Laminated tube structures in both types use multiple layers, but plastic barrier laminate often relies on advanced polymers like EVOH for barrier protection, while aluminum laminated tubes use a thin foil layer.

- The shelf life of products in plastic barrier laminate tubes is generally better than in paper laminates, but not as long as in metal or glass containers.

| Packaging Material | Shelf Life Comparison | Barrier Properties |

|---|---|---|

| Plastic Barrier Laminates | Better than paper laminates | Superior protection against moisture and oxygen |

| Paper Laminates | Needs extra processing for performance | Good for dry goods, less effective than plastic |

| Metal and Glass | Longest shelf lives due to impermeability | Impermeable to gases, light, and moisture |

Environmental Impact

The environmental impact of laminated tube packaging depends on the materials used. Aluminum barrier laminate tubes have a recyclability rate of about 30% in major markets. There is no specific data for the recyclability rate of plastic barrier laminate tubes, making direct comparison difficult. However, environmental assessments show that aluminum foil laminates have a higher impact on metal depletion, fossil depletion, and global warming potential than metallized polymer laminates. Metallized polymer laminate tubes reduce metal depletion by 71% and fossil depletion by 21% compared to aluminum foil. The global warming potential of these laminated tubes is also half that of aluminum foil laminated tubes. These findings highlight the environmental advantages of plastic barrier laminate tubes in reducing resource use and emissions throughout their life cycle.

Note: Choosing the right laminated tube depends on the balance between barrier protection, shelf life, product integrity, and environmental considerations.

Eco-Friendly Features

Recyclability

Laminated tube packaging stands out for its recyclability. Many manufacturers have developed processes to recycle post-industrial plastic from their factories. For example, Essel Propack has blended recycled plastic with HDPE to create new products. The company also launched a project to recycle aluminum barrier laminated tubes by separating materials without heat or chemicals. Independent testing confirmed that blends of recycled materials from laminated tube production meet critical guidance requirements for recyclability.

However, recycling facilities face several challenges when processing laminated tube packaging:

- Complexity of multi-layer films makes separation difficult.

- Adhesion between layers often exceeds the strength of the films.

- Economic viability remains a concern due to low prices for virgin plastics.

Despite these challenges, advances in recycling technology continue to improve the recyclability of plastic barrier laminate tubes. Regulatory requirements in regions like the European Union now demand that all packaging be recyclable by 2030. Producers must ensure that laminated tube designs support recycling and include recycled content where possible.

Reduced Environmental Footprint

Plastic barrier laminate packaging offers significant environmental advantages over traditional materials. The structure of laminated tubes provides strong barrier protection, which helps extend shelf life and reduce product waste. Compared to glass beverage bottles, laminated tube packaging uses less energy and produces fewer greenhouse gas emissions.

| Packaging Type | Greenhouse Gas Emissions | Energy Usage |

|---|---|---|

| Plastic Barrier Laminate | 7 times less | 5 times less |

| Glass Beverage Bottles | Higher | Higher |

Laminated tube packaging also supports a circular economy by allowing the use of recycled materials in new laminate tubes. The barrier protection in these tubes ensures that products remain safe and effective throughout their shelf life. As a result, companies can meet both environmental goals and regulatory standards for recyclable packaging.

Applications of PBL

Packaging Uses

Plastic barrier laminate finds widespread use in many industries due to its versatility and protective qualities. Companies rely on laminated tube packaging to deliver products that require strong barrier protection and extended shelf life. The most common applications include:

- Cosmetics: Laminated tubes package skin creams, lotions, and serums, offering both product protection and visual appeal. Skin care packaging benefits from the barrier properties of these tubes, which help maintain product quality.

- Food: Laminated tubes hold sauces, pastes, and condiments, ensuring freshness and preventing spoilage. The barrier layers contribute to shelf life extension, making these tubes ideal for food products.

- Pharmaceuticals: Laminated tubes store topical creams, ointments, and gels. These tubes maintain the efficacy of medications by protecting them from moisture and contaminants.

Laminated tube packaging supports a sustainable packaging solution by combining recyclability with high performance.

The following table highlights real-world examples of laminated tube applications across various sectors:

| Application Area | Description |

|---|---|

| Food | Suitable for packaging various food products, enhancing shelf life while being recyclable. |

| Home and Personal Care | Effective for packaging home and personal care items, promoting sustainability. |

| Pharmaceuticals | Can package pharmaceutical products, ensuring barrier performance and recyclability. |

| Coffee | Designed for coffee packaging, allowing brands to shift to recyclable options. |

| Snacks | Ideal for snack packaging, contributing to reduced carbon footprint. |

| Dry Pet Food | Supports the packaging of dry pet food, aligning with eco-friendly practices. |

| Baby Nutrition | Suitable for baby nutrition products, ensuring safety and recyclability. |

Industry Trends

Sustainability trends continue to shape the adoption of laminated tube packaging. Food manufacturers and retailers now choose recyclable barrier laminates to meet consumer demand for environmentally responsible products. Regulatory agencies such as the EPA and FDA enforce stricter guidelines on packaging materials, pushing companies to innovate with biodegradable polymers and recycled content.

The demand for laminated packaging materials has grown rapidly over the past five years. Key drivers include a preference for convenient packaging, increased food safety awareness, and a shift toward sustainable packaging solutions. Industry reports project a compound annual growth rate of 5-7% for laminated tubes, with the market expected to reach $6.7 billion by 2025 and $10.1 billion by 2035.

- Consumer preferences drive the adoption of eco-friendly packaging. There is a 20% annual growth in demand for recyclable and bio-based laminate tubes, especially in Europe.

- Manufacturers now develop mono-material PE laminate tubes that are fully recyclable while maintaining barrier properties.

- The global push for reduced plastic waste accelerates the adoption of sustainable alternatives.

Brands such as ExxonMobil have launched recyclable high-barrier laminates to address both regulatory requirements and consumer expectations. As a result, laminated tube packaging stands out as a leading choice for companies seeking to balance product protection, shelf stability, and environmental responsibility.

Conclusion

Plastic barrier laminate stands out as a greener choice because it supports recycling, reduces waste, and maintains product integrity. Brands select laminated packaging for its environmental sustainability, barrier protection, and versatility in design. Laminated tube manufacturing offer physical flexibility and suit many applications, ensuring product freshness and extending shelf life. Sustainability experts recommend designing laminated tubes for recyclability and using mono-material solutions. The market for laminate tubes continues to grow as regulations favor eco-friendly options. Companies that adopt laminated packaging help drive innovation and meet global sustainability goals, making lami tubes production essential for a better future.

FAQ

What Makes Plastic Barrier Laminate More Sustainable than Traditional Packaging?

Plastic barrier laminate uses fewer resources and supports recycling. Manufacturers can include recycled content in new tubes. This approach reduces waste and helps protect the environment.

Can Consumers Recycle PBL Tubes at Home?

Most recycling programs accept PBL tubes if they use mono-material designs. Consumers should check local recycling guidelines. Some areas require special drop-off locations for laminated tube packaging.

How Does PBL Protect Products Inside the Tube?

PBL uses multiple layers to block moisture, oxygen, and light. This structure keeps products fresh and safe. The barrier also helps extend shelf life.

Are PBL Tubes Safe for Food And Pharmaceuticals?

Manufacturers design PBL tubes to meet strict safety standards. These tubes do not react with food or medicine. Regulatory agencies approve their use for sensitive products.

What Industries Benefit Most from PBL Packaging?

Cosmetics, food, and pharmaceutical companies use PBL packaging. These industries need strong barrier protection and recyclable solutions. PBL meets both needs and supports sustainability goals.