Manufacturing industries face rising demands for tube sealing as global market size reaches USD 3.42 billion in 2024, with projections of USD 5.07 billion by 2034.

| Aspect | Details |

|---|---|

| Market Size (2024) | USD 3.42 billion |

| Market Projection (2034) | USD 5.07 billion |

| CAGR (2025-2034) | ~4.0% |

| Automatic Machines Market Share (2025) | 61.3% |

| Key Growth Drivers | Automation, sustainability, pharma, cosmetics, food industries |

Automation, hygiene, and sustainability drive manufacturers to seek faster, cleaner, and more precise sealing methods.

Ultrasonic welding offers advanced ultrasonic technology that meets these requirements. Companies now turn to ultrasonic solutions for efficient tube sealing and reliable packaging.

Key Takeaways

- Ultrasonic welding speeds up tube sealing by creating strong seals in less than a second, boosting production and saving energy.

- Automation with ultrasonic welding cuts labor costs and errors, making manufacturing faster and more reliable.

- This technology produces clean, strong seals without adhesives or heat damage, protecting sensitive products and reducing waste.

- Ultrasonic welding uses less energy and creates no harmful emissions, supporting safer workplaces and eco-friendly packaging.

- Though initial costs are higher, ultrasonic welding offers quick return on investment through lower energy use, less waste, and reduced labor.

Ultrasonic Welding Advantages

Speed and Efficiency

Ultrasonic welding delivers unmatched speed and efficiency in tube sealing applications. Manufacturers using ultrasonic sealing experience faster production cycles compared to traditional heat sealing methods. For example, the Falcon-KN ultrasonic tube sealing machine can perform up to 20 welds per minute, which significantly increases throughput. Quick tooling changes, often completed in under three minutes, further enhance operational efficiency.

| Welding Method | Average Cycle Time per Weld |

|---|---|

| Ultrasonic Welding | Approximately 0.5 to 1 second |

| Resistance Welding | Approximately 3 to 6 seconds |

| Arc Welding | Approximately 5 to 10 seconds or more |

Ultrasonic tube sealing machines operate with high efficiency, requiring less energy and producing consistent, high-quality seals. The technology enables rapid fabrication of packaging materials without impurities or thermal distortions. This process supports high-speed operation, allowing manufacturers to process hundreds of units per minute. Companies using lami tube making machine benefit from these advantages, achieving efficient sealing for laminated tube in industries such as cosmetics and pharmaceuticals.

Tip: Ultrasonic sealing increases production capacity and helps manufacturers outperform competitors by improving product quality and operational efficiency.

Automation and Labor Savings

Automation plays a critical role in the adoption of ultrasonic welding for tube sealing. Ultrasonic sealing eliminates manual handling, reducing labor costs and improving process reliability. The equipment is modular and user-friendly, simplifying operation and minimizing downtime. Manufacturers report significant reductions in labor time and training needs due to the fast, repeatable, and easily automated nature of ultrasonic welding.

Ultrasonic sealing integrates seamlessly into automated production lines. Features such as multi-probe control, trigger by power, and precise weld modes enable flexible, repeatable welds with minimal variability. These capabilities reduce human error and ensure consistent seal quality. The process also minimizes downtime and maintenance, allowing easier adaptation to changes in supply chain or manufacturing requirements.

- Automation reduces manual handling variations and production bottlenecks.

- Ultrasonic welding supports high-volume manufacturing with reliable, repeatable results.

- Labor expenses decrease as training and operation become simpler.

Laminated tube making machine equipped with ultrasonic sealing technology demonstrates these benefits, producing laminated tubes with consistent seals and lower labor costs.

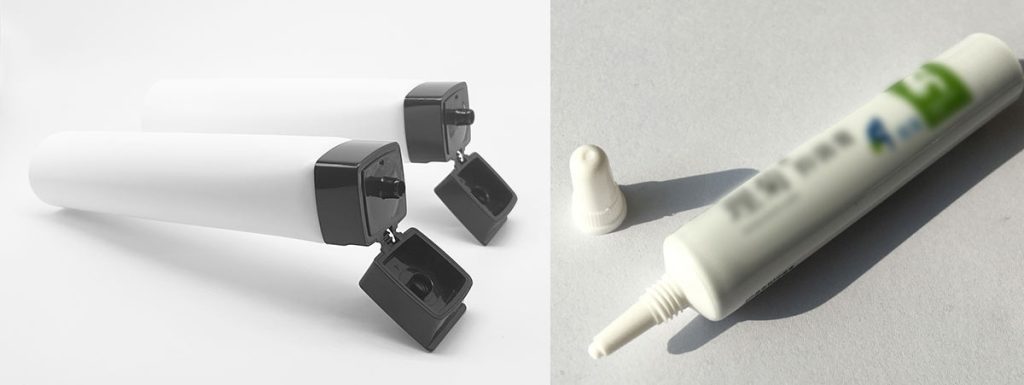

Clean and Strong Seals

Ultrasonic welding produces clean, strong seals that meet the highest standards for tube sealing. The process uses high-frequency vibrations to generate localized heat, creating hermetic seals suitable for sensitive products such as food and pharmaceuticals. Ultrasonic sealing eliminates the need for adhesives or solvents, reducing contamination risks and material waste.

- Ultrasonic welding creates short weld times, typically under one second, enabling high-volume production.

- The process is clean and suitable for clean-room environments, producing sealed edges without stitch holes.

- Minimal thermal damage occurs because heat is localized at the joint interface.

- The resulting seam is impermeable, essential for applications requiring strong, contamination-free seals.

Studies show that ultrasonic welding achieves weld strengths up to 90% of the base material, especially in laminated tube applications. The technology is versatile, joining thermoplastics and non-woven materials without causing polymer or fiber degradation. Manufacturers use ultrasonic sealing for products such as diapers, auto seat covers, and leak-proof filter bags, demonstrating its suitability for a wide range of materials.

Note: Ultrasonic sealing supports high efficiency and sustainability goals by reducing carbon footprint and material waste.

Ultrasonic welding stands out as a reliable solution for efficient sealing, offering high efficiency, strong seals, and clean processing for laminated tube and other packaging applications.

How Ultrasonic Technology Works?

The Sealing Process

Ultrasonic technology transforms tube sealing by using high-frequency vibrations to create strong, clean bonds. The sealing process begins when the tube is placed between an ultrasonic horn and an anvil. The horn vibrates at ultrasonic frequencies, generating frictional heat inside the thermoplastic material. This localized heat melts the tube edges, and pressure from the horn and anvil fuses the material together. The process does not require preheating or cooling, which allows for near-instantaneous sealing.

- Key steps in ultrasonic sealing:

- Position the tube between the horn and anvil.

- Activate the horn to vibrate at ultrasonic frequency.

- Generate internal heat and melt the tube edges.

- Apply pressure to form a strong, clean seal.

- Remove the sealed tube, ready for the next cycle.

Unlike traditional heat sealing, ultrasonic technology operates at lower temperatures. This protects heat-sensitive products such as cosmetics and pharmaceuticals. The process also tolerates minor product contamination in the sealing area, reducing waste and improving reliability. Scientific principles such as the piezoelectric effect and magnetostriction drive ultrasonic sealing. These effects convert electrical energy into mechanical vibrations, which are then amplified and directed to the sealing interface. This precise control ensures efficient energy transfer and consistent results.

Energy and Environmental Benefits

Ultrasonic technology offers significant energy and environmental advantages over traditional sealing methods. Ultrasonic sealing consumes up to 75% less energy than heat sealing because it only draws power during the actual sealing process. There is no need for preheating or continuous heating elements, which reduces operational costs and carbon footprint.

| Environmental Aspect | Ultrasonic Welding | Traditional Welding |

|---|---|---|

| Heat Source | High-frequency vibrations, low heat generation | Arc/flame/electric, high heat |

| Material Consumption | No filler materials or adhesives needed | Requires filler materials and adhesives |

| Emissions and Pollution | No fumes, sparks, or smoke produced | Produces smoke, fumes, and residue |

| Energy Efficiency | High energy efficiency, fast cycle times | Higher power consumption, slower process |

| Operator Safety | Safer, no harmful emissions or UV light exposure | Exposure to smoke, UV light, sparks; requires PPE |

| Post-processing | Minimal to none, clean welds | Requires cleanup to remove residue and oxidation |

| Automation and Speed | Easily automated, very fast cycle times | Slower, less automation ready |

Ultrasonic technology eliminates the need for adhesives or solvents, further reducing material waste and environmental impact. The process produces no fumes, sparks, or smoke, creating a safer and cleaner work environment. Manufacturers benefit from faster cycle times, lower energy bills, and improved sustainability. Ultrasonic sealing stands out as a responsible choice for modern tube sealing operations.

Ultrasonic Sealing vs. Heat Sealing

Process Control and Flexibility

Ultrasonic sealing provides manufacturers with advanced process control and flexibility that surpass traditional heat sealing. Operators can program and adjust over a dozen critical parameters, including amplitude, pressure, and weld time. This level of control ensures consistent, repeatable results, even when working with challenging or sensitive materials. In contrast, heat sealing relies on managing only a few variables: temperature, pressure, dwell time, and cooling time. This limitation can lead to inconsistent seals and higher risk of product damage.

A comparative overview highlights these differences:

| Aspect | Ultrasonic Sealing | Heat Sealing |

|---|---|---|

| Process Control | Precise, programmable control over 12+ factors | Controls mainly temperature, pressure, dwell time, and cooling time |

| Heat Generation | Heat generated only within the material via vibration | Heat applied externally, requiring strict temperature control |

| Sealing Speed | Fast sealing (100-200 ms), no cooling phase | Requires cooling phase to solidify bond |

| Flexibility | High flexibility, supports newer materials | Less flexible, requires strict parameter management |

| Risk of Damage | Lower risk due to localized heat | Higher risk of uneven sealing and damage |

| Seal Reliability | High precision reduces leakage risk | Dependent on strict control of multiple parameters |

Ultrasonic sealing also supports rapid changeovers and flexible production runs. Operators can quickly modify process settings without waiting for equipment to heat up or cool down. This adaptability allows manufacturers to respond to changing production needs and material innovations.

Note: Studies show that ultrasonic sealing consumes energy only during the sealing process, while heat sealing requires continuous heating, leading to higher energy costs and less flexibility.

Material and Application Range

Ultrasonic sealing accommodates a wide range of materials and applications, making it a preferred choice for modern manufacturing. The technology excels in speed, precision, and minimal distortion, which proves essential for high-volume production and sensitive products. Manufacturers use ultrasonic sealing for thermoplastics, biodegradable polymers, and non-woven materials, including those found in medical, food, and cosmetic packaging.

- Ultrasonic sealing uses high-frequency vibrations to generate heat precisely at the interface, allowing controlled melting and bonding.

- The process removes contaminants from sealing surfaces, improving reliability and reducing failures.

- Cycle times can be as short as 150 milliseconds, with no cooling phase required.

- The technology suits temperature-sensitive products, as heat is localized and brief.

- Equipment allows rapid changeovers and flexible adjustments, supporting diverse production needs.

- Energy consumption remains low, as power is applied only during the sealing cycle.

- Advanced control methods enable precise regulation of heat and pressure, improving consistency.

While heat sealing can work with a broad spectrum of materials, ultrasonic sealing stands out in applications where precision, speed, and contamination control are critical. Manufacturers benefit from strong, hermetic seals and the ability to handle new, sustainable materials that challenge traditional methods.

Sealing Benefits for Tubes

Leak Prevention

Ultrasonic sealing technology delivers superior leak prevention for tube applications. Manufacturers rely on this method because it creates molecular bonds that remain intact even when product residue is present in the sealing area. This accuracy results in fewer leaks and cleaner equipment, which is essential for industries handling liquids or sensitive products. The process works efficiently with both solids and liquids, making it suitable for a wide range of packaging needs. Lami tube making machine equipped with ultrasonic systems produces laminated tubes with consistent, airtight seals. These seals operate at low temperatures, preserving heat-sensitive products and avoiding failures common in traditional heat sealing. The technology also produces smaller seals, which reduces raw material waste while maintaining effective sealing performance. Ultrasonic sealing uses high-frequency vibrations to melt tube materials, forming a strong and reliable seal that protects against leaks and contamination. This method extends product shelf life by shielding contents from external factors.

Product Integrity

Maintaining product integrity stands as a critical goal in tube packaging. Ultrasonic welding achieves high precision, ensuring excellent cutting and sealing effects on metal and plastic tubes. Advanced control devices allow operators to tune and monitor welding quality, resulting in consistent and optimal seals. The process creates strong, hermetic seals on copper, aluminum, and laminated tube materials, preventing leaks and preserving product quality. Lami tube making machine benefits from simultaneous welding and cutting, which improves efficiency and reliability. Ultrasonic sealing forms permanent, molecular bonds without adhesives, ensuring clean and strong seals. These features prevent product loss, moisture intrusion, and pest infiltration. Rotary ultrasonic solutions deliver continuous power, enabling faster and more consistent sealing cycles. Programmable control features ensure repeatable welds, eliminating weak points and holes that compromise integrity. Products such as cosmetics, pharmaceuticals, and food items remain intact and reliable throughout their shelf life.

Waste Reduction

Ultrasonic tube sealing technology supports waste reduction in modern packaging operations. Laminated tube making machine uses high-frequency vibrations to create precise seals quickly and with less energy than traditional heat sealing. This efficiency leads to reduced material waste and lower energy consumption. Ultrasonic sealing enables sealing through contaminants, which improves product safety and reduces packaging defects. The technology’s precision and reliability contribute to less material waste, supporting eco-friendly packaging initiatives. Industries such as cosmetics, food and beverage, and pharmaceuticals adopt ultrasonic sealing for laminated tube manufacturing to minimize spillage risks and enable the use of biodegradable materials. The process aligns with sustainability goals by reducing the likelihood of product spillage or contamination. Minimal energy consumption and compatibility with biodegradable materials further enhance waste reduction efforts, making ultrasonic sealing a preferred choice for responsible packaging.

Practical Considerations

Cost and ROI

Manufacturers evaluating ultrasonic welding for tube sealing must consider both initial investment and long-term savings. The upfront equipment cost ranges from $18,000 to $45,000, with most systems averaging around $30,000. Although this represents a higher initial outlay compared to traditional methods, the investment pays off through durability and reduced maintenance. Tooling costs are higher at the start, but the tools last longer and require fewer replacements. Energy consumption drops significantly, as ultrasonic welding uses only about 5% of the energy required by resistance welding. Labor costs decrease because the process often eliminates the need for at least one worker and reduces workplace injuries.

| Cost Component | Ultrasonic Welding Details | Comparison to Traditional Methods |

|---|---|---|

| Equipment Cost | $18,000 to $45,000; typical system around $30,000 | Higher initial investment but offsets with durability |

| Tooling Cost | Higher upfront, lasts longer, less maintenance | Frequent replacement needed |

| Energy Cost | Uses about 5% of resistance welding energy | Much lower consumption |

| Labor Cost | Reduces workforce, fewer injuries | Labor savings, improved safety |

| Joint Quality | Strong, water-resistant, impact-resistant joints | Better quality, less waste |

| Environmental Impact | No fumes or consumables | More eco-friendly |

Return on investment for ultrasonic welding proves attractive. For a production volume of 100,000 units, manufacturers often recover their investment within 12 months. At 1,000,000 units, the ROI period extends to about 18 months. These results stem from labor cost savings of up to 70%, material waste reduction of 85%, and quality control savings of 50%. Lower energy bills and faster production cycles further improve cost efficiency.

Tip: Ultrasonic welding reduces raw material usage by creating smaller, more precise seals, which lowers both material costs and waste.

Integration and Limitations

Integrating ultrasonic welding into existing production lines requires careful planning. Several technical requirements must be met for successful adoption. Key components include a power supply, transducer, booster, sonotrode (horn), anvil, and pneumatic actuator. The system must operate within a 20-40 kHz frequency range and offer precise control over time, energy, amplitude, and pressure. Digital control systems and ergonomic designs help operators adapt to various tube diameters and materials.

However, some challenges may arise:

- Material hardness affects weld quality. Softer plastics weld easily, while harder materials need more energy and optimized joint design.

- Material thickness can limit production speed, as thicker tubes require more heat and time.

- Moisture content in materials may disrupt welding, so pre-drying is often necessary.

- Complex part shapes might need customized tooling to ensure consistent welds.

- Material compatibility is critical. Dissimilar materials with different melting points or acoustic properties can result in weak bonds.

- Tooling wear from abrasive fillers can reduce energy transfer and cause cosmetic damage.

Manufacturers should collaborate with ultrasonic welding experts early in the process. Maintaining strict process control and documentation ensures consistent weld quality. For industries seeking advanced packaging technology, ultrasonic welding offers a reliable, efficient, and sustainable solution, provided these integration factors are addressed.

Conclusion

Ultrasonic welding stands out as a future-ready solution for tube sealing. Industry experts highlight its rapid process times, cold tool operation, and low energy use. Manufacturers benefit from clean, reproducible seals and seamless integration with automation.

- No solvents or additives are needed, supporting sustainability and recyclability.

- Real-world applications show improved product quality, reduced waste, and lower maintenance.

Regulatory bodies recommend ultrasonic processes for contamination-free, traceable welds. Companies seeking speed, efficiency, and environmental responsibility should consider ultrasonic technology for their sealing needs.

FAQ

What Types of Tubes Can Ultrasonic Welding Seal?

Ultrasonic welding seals thermoplastic, laminated, and some metal tubes. Manufacturers use this technology for cosmetic, pharmaceutical, and food packaging. The process works well with both rigid and flexible tube materials.

Does Ultrasonic Welding Affect Product Quality?

Ultrasonic welding preserves product quality. The process uses localized heat, which protects heat-sensitive contents. Seals remain strong and clean, reducing contamination risks and maintaining product integrity.

How Does Ultrasonic Welding Improve Sustainability?

Ultrasonic welding reduces energy use and material waste. The process eliminates adhesives and solvents, lowering environmental impact. Manufacturers achieve cleaner production and support eco-friendly packaging initiatives.

Is Ultrasonic Welding Safe for Operators?

Ultrasonic welding offers a safer work environment. The process produces no fumes, sparks, or harmful emissions. Operators face less risk of burns or exposure to hazardous substances.

Can Ultrasonic Welding Integrate with Automated Lines?

Manufacturers can easily integrate ultrasonic welding into automated production lines. The technology supports modular setups, digital controls, and rapid changeovers, which increase efficiency and reduce manual labor.