Choosing a laminated tube making machine delivers unmatched advantages over alternative brands. Companies gain versatility, speed, and reliability for skin care packaging and beyond.

- The laminated tube making machine handles various tube sizes and product types, meeting demands in cosmetics and pharmaceuticals.

- Advanced robotics and AI boost efficiency and accuracy, preserving product integrity.

- Superior barrier properties protect contents, ensuring longer shelf life.

- Market data shows laminated tubes will capture 36.1% of the packaging market by 2025.

| Competitive Advantage | Description |

|---|---|

| Technological Advancements | Innovations reshape the industry, driving competitiveness. |

| Value Chain Optimization | Efficiency improvements enhance operational performance. |

| Customer Preferences and Trends | Insights help businesses tailor offerings, improving satisfaction and growth. |

| Emerging Technologies | Innovation creates new growth opportunities. |

Key Takeaways

- The laminated tube making machine offers unmatched versatility, handling various tube sizes and materials for diverse industries like cosmetics and pharmaceuticals.

- Advanced automation features enhance production efficiency, reducing downtime and ensuring consistent quality in every batch of laminated tubes.

- Customization options allow brands to create unique packaging that reflects their identity, improving shelf presence and customer satisfaction.

- Energy-saving technologies lower operating costs, making the machine a cost-effective choice for manufacturers committed to sustainability.

- Outstanding customer support and training ensure smooth operation, empowering teams to maximize productivity and minimize errors.

Performance

High Efficiency

The lami tube making machine stands out for its remarkable performance in demanding production environments. Companies experience a significant boost in output when they choose this machine over alternative brands. The advanced design allows operators to maintain high levels of efficiency, even during long production runs.

Customers report that the lami tube making machine consistently delivers reliable results, reducing downtime and maximizing productivity.

A key factor behind this superior performance is the machine’s ability to streamline the entire manufacturing process. The in-line production method ensures a strong bond between the tube body and head, which means fewer defects and less waste. Compression moulding for plastic tube heads eliminates the need for pre-formed components, further enhancing efficiency.

Faster Production

Speed matters in today’s competitive market. The laminated tube making machine leads the industry with its rapid production rates. Consider the following comparison:

| Machine Type | Production Speed (Tubes/Min) |

|---|---|

| HSL – UHSL | Up to 240 TPM |

| LMS/TET | Up to 150 TPM |

The HSL – UHSL model achieves up to 240 tubes per minute, while the LMS/TET system reaches 150 tubes per minute. These speeds far surpass those of many alternative brands, allowing manufacturers to fulfill large orders quickly and meet tight deadlines.

- The LMS/TET system uses a continuous process for producing laminate tube bodies.

- The in-line method guarantees a reliable bond and smooth workflow.

- Operators can switch between tube sizes with minimal downtime.

This exceptional performance gives businesses a clear advantage. They can respond faster to market demands and deliver high-quality laminated tube packaging to their customers.

Laminated Tube Making Machine

Multi-Material Handling

The lami tube making machine sets a new standard for versatility in packaging. Manufacturers can process a wide range of materials, ensuring that laminate tubes meet the highest demands for protection and appearance. Unlike alternative brands, this machine handles both aluminum barrier laminate and plastic barrier laminate with ease. Each material offers unique benefits for packaging, from excellent barrier properties to enhanced recyclability.

| Material Type | Description | Applications |

|---|---|---|

| Aluminum Barrier Laminate (ABL) | Multi-layered with aluminum foil for excellent protection against light, oxygen, and moisture. | Oral Care, Cosmetics, Pharmaceuticals, Food, Industrial |

| Plastic Barrier Laminate (PBL) | All-plastic layers with an EVOH barrier for flexibility and recyclability. | Oral Care, Cosmetics, Pharmaceuticals, Food, Industrial |

This advanced multi-material capability allows companies to select the ideal laminate for every product. Laminate tubes produced on this machine deliver superior protection for sensitive contents. The result is packaging that extends shelf life and maintains product quality. Businesses gain a competitive edge by offering laminate tubes that perform in any environment.

Tip: Choosing the right laminate material ensures that packaging stands out on the shelf and meets strict industry standards.

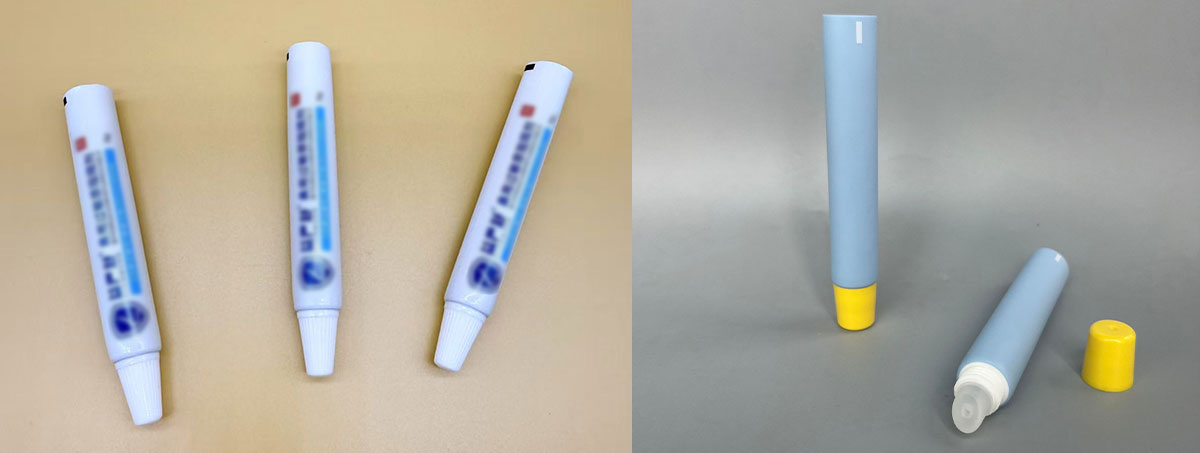

Customization for Laminate Tubes

Customization options empower brands to create laminate tubes that reflect their unique identity. The lami tube making machine supports a wide range of customization features, from material selection to design elements. Companies can choose from various head styles, cap options, and printing methods to match their branding and product requirements.

| Customization Option | Description |

|---|---|

| Material Choices | Options include Aluminum Barrier Laminate (ABL), All Plastic Tube (APT), PCR APT, and Plastic Barrier Laminate (PBL). Each material offers unique barrier properties and aesthetics. |

| Head Styles and Cap Options | Various head styles such as screw on, nasal, and lip slant, along with custom tooling for unique designs. |

| Printing Methods | Multiple printing options including offset printing, silk screening, and flexographic printing, allowing for high-quality graphics and branding. |

| Sustainability Features | Options like PCR APT made from recycled materials cater to eco-conscious customers. |

- Laminate tubes offer excellent barrier properties, protecting contents from light, moisture, and oxygen.

- Customizable sizes and shapes help brands create packaging that fits their vision.

- Advanced printing methods make laminate tubes visually appealing and boost shelf presence.

The lami tube making machine delivers unmatched versatility for laminate tubes. Brands can respond to market trends, launch new products quickly, and satisfy diverse customer needs. With this level of customization, packaging becomes a powerful tool for differentiation and growth.

Technology

Advanced Automation

Manufacturers demand precision and speed in every production run. The lami tube making machine delivers both through advanced automation. Smart sensors and vision systems powered by AI monitor every stage of the process. These systems minimize human intervention and reduce production errors. Operators see fewer mistakes and more consistent results.

- Advanced automation enhances precision, speed, and reliability in the manufacturing process.

- Smart sensors and vision systems powered by AI minimize human intervention and reduce production errors.

- Adaptive control allows machines to dynamically adjust parameters based on material and content viscosity, optimizing throughput and minimizing waste.

- AI-driven predictive maintenance forecasts potential faults, reducing downtime and enhancing operational efficiency.

Adaptive control technology allows the machine to adjust settings for different materials, including high-performance plastics and various barrier layer combinations. This flexibility ensures that every laminated tube meets strict standards for barrier properties and maximum protection. AI-driven predictive maintenance also reduces downtime, keeping production lines running smoothly.

Automation in the lami tube making machine means faster changeovers, less waste, and higher output. Businesses gain a clear advantage in efficiency and product quality.

Consistent Quality

Customers expect high-quality packaging every time. The lami tube making machine guarantees this with fully automatic equipment designed for high-speed and high-volume production. Automated cleaning, real-time monitoring, and data analytics work together to maintain reliability and consistent results.

- Fully automatic equipment is designed for high-speed and high-volume production, ensuring consistent quality and efficiency.

- Advanced features like automated cleaning, real-time monitoring, and data analytics enhance the reliability of these machines.

- Accurate measurement through sensors and pumps ensures every tube receives the same amount, maintaining quality.

- Strong seals prevent air and moisture from compromising the product.

Accurate sensors and pumps deliver the exact amount of product into each tube. Strong seals, created by advanced barrier layer technology, prevent air and moisture from entering. This process preserves the superior barrier protection and barrier properties that customers require. The result is high-quality packaging that extends shelf life and maintains product integrity.

The lami tube making machine uses laminate materials with multiple barrier layers. These layers provide barrier properties that protect sensitive contents from light, oxygen, and moisture. Companies can trust this machine to deliver high-quality laminated tubes with extended shelf life and maximum protection for every product.

Reliability

Stability And Uptime

Manufacturers rely on machines that deliver consistent performance day after day. The lami tube making machine demonstrates outstanding durability and uptime, setting a new standard for reliability in the industry. Operators experience fewer interruptions and maintain high productivity levels. The advanced design includes digital position indicators and recipe storage for settings, which streamline changeovers and reduce errors.

High durability means fewer breakdowns and less maintenance, allowing teams to focus on production instead of repairs.

The following table highlights how the FlexSeamer model compares to alternative brands:

| Feature | FlexSeamer (PackSys Global) | Alternative Brands (General) |

|---|---|---|

| Speed | 250 tubes per minute | Varies |

| Position Indicators | Digital | Mechanical |

| Changeover Monitoring | Yes | No |

| Quality Consistency | High | Varies |

| Recipe Storage for Settings | Yes | No |

FlexSeamer’s digital controls and monitoring systems ensure stable operation. Alternative brands often use mechanical indicators, which can lead to more downtime and inconsistent results. The ability to store recipes for different laminate tubes boosts efficiency and reliability. Companies benefit from high-speed production and consistent quality, making the lami tube making machine a smart investment.

Compact Design

Space matters in modern manufacturing environments. The compact design of the lami tube making machine offers significant advantages for businesses with limited floor space. Teams can easily mobilize the robust structure, making installation and relocation simple. The flexible nature of the machine allows operators to adapt quickly to changing production needs.

- Collapsible tubes are light and space efficient, making them easy to transport and store.

- The overall structure is highly robust and compact, which can be easily mobilized.

This space-saving design supports efficient workflow and reduces clutter. Companies maximize their available area without sacrificing performance or durability. The compact footprint also makes it easier to integrate the machine into existing production lines. Laminate tubes benefit from the durability and flexibility of the machine, ensuring reliable packaging for every product.

Businesses that choose a compact, durable machine gain more than just space—they secure long-term reliability and flexible production options.

Cost-Effectiveness

Low Energy Use

The lami tube making machine stands out for its energy-saving features. Manufacturers see real savings thanks to smart systems like Energy Saving Mode and Automatic Shutdown. These features help reduce electricity consumption during idle times and non-peak hours. As a result, businesses lower their utility bills and support environmental sustainability.

Energy-efficient machines not only cut costs but also show a commitment to green manufacturing.

A closer look at sustainability reveals more advantages. Laminated tubes use advanced materials that combine plastic and aluminum for strong barriers. Many models now move toward mono-material solutions, making recycling easier. Some even use bio-based or biodegradable plastics, giving companies more eco-friendly options.

| Feature/Benefit | Laminated Tubes | Alternative Brands |

|---|---|---|

| Material Composition | Combines plastic and aluminum for barriers | Varies, often single material |

| Barrier Properties | Superior protection against moisture, air, and light | May not provide same level of protection |

| Recycling Potential | Moving towards mono-material solutions | Often complex due to multi-materials |

| Eco-Friendly Options | Bio-based and biodegradable plastics | Limited sustainable options |

Reduced Operating Costs

Companies that invest in the lami tube making machine experience real cost savings. Industry 4.0 technologies, such as real-time quality monitoring and predictive maintenance, boost productivity by up to 30%. These advancements also reduce operational costs by about 20%. Fewer breakdowns and less waste mean teams spend less on repairs and materials.

- Real-time monitoring catches defects early, reducing scrap rates.

- Predictive maintenance prevents unexpected downtime.

- Automated systems require fewer operators, lowering labor costs.

The cost-effectiveness of the lami tube making machine gives businesses a clear advantage. They can produce high-quality laminate tubes while keeping expenses low. This smart investment helps companies stay competitive and profitable in a fast-changing market.

User Experience

Easy Operation

Operators find the lami tube making machine remarkably simple to use. The intuitive interface guides users through every step, reducing the chance of errors. Clear displays and touch controls allow staff to adjust settings quickly. This design ensures that even new team members can operate the machine with confidence.

Production staff benefit from user-friendly features built into the laminated tube making machine.

- Flip-top caps, screw caps, and nozzle applicators make opening, closing, and dispensing effortless.

- The machine’s streamlined workflow reduces manual handling, which leads to fewer mistakes and higher output.

- Automated cleaning and maintenance routines further enhance convenience for operators.

These features create a smooth production process. Teams spend less time troubleshooting and more time focusing on quality. The result is greater consumer convenience, as products reach the market faster and in perfect condition.

Operators appreciate the convenience of a machine that adapts to their needs and simplifies daily tasks.

Minimal Training

Companies save valuable time and resources with the minimal training required for the lami tube making machine. The straightforward controls and logical layout mean that new operators learn quickly. Training sessions focus on practical skills, not complex theory.

- Teams experience better working conditions because the machine reduces repetitive tasks.

- Staff members feel empowered to take on new responsibilities, which boosts morale and productivity.

- The clear instructions and visual cues help operators avoid common mistakes.

Managers notice a rapid improvement in efficiency after introducing the machine. Employees adapt to new production demands without lengthy training periods. This advantage allows businesses to scale up operations or shift production lines with ease.

The lami tube making machine transforms the user experience. It delivers unmatched convenience, supports staff development, and ensures that every laminate tube meets the highest standards.

Support

Customer Service

Outstanding customer service sets the lami tube making machine apart from alternative brands. The support team responds quickly to every inquiry. They guide users through installation, troubleshooting, and routine maintenance. Customers receive clear answers and practical solutions. This level of service helps companies keep their laminated tube production running smoothly.

Tip: Fast response times reduce downtime and protect profits.

The support staff understands the challenges manufacturers face. They offer advice tailored to each production environment. Users gain confidence knowing help is always available. The team provides updates on new features and best practices. This proactive approach ensures that every business maximizes the value of its lami tube making machine.

| Service Feature | Benefit |

|---|---|

| 24/7 Support | Immediate help for urgent issues |

| Technical Guidance | Expert advice for optimal performance |

| Spare Parts Availability | Quick replacement to minimize delays |

Training and Warranty

Comprehensive training empowers operators to master the lami tube making machine quickly. The manufacturer offers hands-on sessions and easy-to-follow manuals. Staff members learn how to operate, clean, and maintain the equipment. This training reduces errors and boosts productivity.

Warranty coverage gives companies peace of mind. The manufacturer stands behind every laminated tube machine with a robust warranty. If a problem arises, the team resolves it without delay. This protection minimizes risk and ensures long-term reliability.

- Training sessions cover setup, operation, and troubleshooting.

- Warranty plans include parts and labor for critical components.

- Ongoing support keeps laminated tube production efficient.

Companies that invest in strong support see fewer breakdowns and higher output.

Reliable customer service, expert training, and solid warranty coverage make the lami tube making machine a smart choice. Businesses gain more than just equipment—they secure a partnership focused on success.

Conclusion

The lami tube making machine delivers unmatched efficiency, versatility, and reliability. Companies gain faster production, multi-material handling, and consistent quality. Superior support and cost savings set this machine apart from alternative brands.

Discover how the right laminated tube solution can transform your business.

Contact the team today for more information or to schedule a live demonstration.

FAQ

What Materials Can the Lami Tube Making Machine Process?

The lami tube making machine handles aluminum barrier laminate and plastic barrier laminate. This flexibility lets manufacturers create laminated tubes for cosmetics, pharmaceuticals, and food products. Businesses can meet diverse packaging needs with one advanced solution.

How Does the Machine Improve Production Efficiency?

The lami tube making machine uses automation and smart controls. Operators see faster changeovers and less downtime. Companies boost output and reduce waste. This machine helps businesses stay ahead in a competitive market.

Is the Lami Tube Making Machine Easy To Operate?

Yes. The machine features an intuitive interface and clear instructions. Operators learn quickly and avoid common mistakes. Minimal training is needed. Teams enjoy a smooth workflow and higher productivity.

What Support Does the Manufacturer Provide?

Customers receive 24/7 support, expert training, and a strong warranty. The team offers fast troubleshooting and spare parts. This support keeps laminated tube production running smoothly and protects your investment.

Can the Machine Produce Custom Laminated Tubes?

Absolutely! The lami tube making machine allows for custom sizes, shapes, and printing options. Brands can create unique laminated tubes that stand out on store shelves and match their product vision.